Well folks, the time has come. We have FINALLY completed our DIY outdoor kitchen build and patio project. It consumed the better part of a year of our lives and tested our endurance and physical, mental, and emotional strength. But alas, it is finally complete(ish) and we're absolutely loving the finished project!

But before we show you where we've ended up, let me remind you of where we started...

Grilling Gift Guide

Looking for gift ideas for yourself or someone special in your life? We've got you covered.

Don't care where we started and just want to see the finished product? Jump here.

Note: Some of the links in this article may be affiliate links. This doesn’t cost you any more than normal but it helps support our channel. Read our disclaimer for more info.

For years we've been operating on this 10x12' concrete slab with a giant crack down the middle. It was certainly better than nothing, but put any furniture on it along with a grill and we were instantly crowded and out of space.

We love to entertain big groups of people, especially in the summer time, so we were always wishing for more room.

Much like the rest of the world, in spring of 2020 we started looking for "pandemic projects" to focus our energy into. We decided that this would be the perfect opportunity to look into expanding and upgrading our outdoor living space.

Decisions, Decisions

We had a lot of decisions to make early on:

The decisions seemed endless. And I'm an analytical guy who sometimes suffers from analysis paralysis so I definitely found this part of the process to be overwhelming.

However, after getting quotes from a few local companies on demo of the old patio and putting in a new one (both stamped and pavers) along with a pavilion and outdoor kitchen (not even units to put in it), we realized that the ONLY way we could ever afford to get the outdoor living space we really want was to do as much of the work as possible ourselves.

DIY it is!

I am not a skilled tradesman. However I am the son of an electrical engineer who designed and built his own house. And let me just say that the knowledge and expertise that he shared with us throughout the last year has been truly invaluable.

However, being on this side of the project, I now understand his reaction when I first shared with him my idea. He knew exactly how much work this would be, and I naively grossly underestimated. All I can say is that Dad earned free filet mignon and shrimp for life in our DIY outdoor kitchen for all the blood, sweat and tears he put into helping us through this project.

Our DIY Outdoor Kitchen Plan

It took several weeks for us to nail down our exact outdoor kitchen plan for what cooking appliances and storage solutions we would be including in our own outdoor kitchen and where it would all go. I'd love to tell you we used some app or free software that designed it for us, and that probably would have made things a lot easier, but we utilized the resources we already had on hand and planned it all out in Adobe Illustrator.

However, we did discover after-the-fact that BBQ Guys offers FREE outdoor kitchen 3D design service, so if you're considering doing a project like this yourself make sure you save yourself some time by having them at least do the design work for you.

Since we were doing the work ourselves we decided it made the most sense to position all of our gas appliances in the same section so the gas line wouldn't have to run to multiple locations. While I still think that made the most sense, that decision did mean limiting our counter space on that side of the outdoor kitchen which is at times frustrating; particularly when using the griddle.

We planned for the majority of our counter space to be all on one side of the outdoor kitchen next to the outdoor sink, and honestly that decision was heavily influenced by the fact that we knew we would be filming YouTube videos from that vantage point and didn't want any large appliances in the way.

If we were planning our DIY outdoor kitchen purely for personal use, we probably would have done it differently and planned our countertop space to be more evenly distributed in all sections. That being said, it is also nice to have that large counter space for food prep as well as buffet space when serving large groups of people.

Storage space was another big thing for us to solve. Doing what we do, we have a lot of tools and equipment that need a home when not being used and it was important for us to use as much available space as possible for storage. You'll see that we did not skimp in the least on storage, but that certainly brought its own challenges when it came to putting up the stone facade later on.

Once we had an idea of where everything was going to go we had to plan out what our electrical needs were, both internally and externally. We placed several outlets on the outside of the outdoor kitchen knowing that they would be needed for lights and other equipment when filming. We also needed internal outlets wherever we had appliances that required electricity.

In addition to the DIY outdoor kitchen plan, we wanted to still have plenty of outdoor living space to accommodate a dining table and chairs as well as a fire pit and outdoor seating area.

Demolition: Out With The Old

Before we could build anything new, we had to get rid of the old. So we rented a skid-steer and set to work. This was the weekend that we got our first glimpse of "This DIY outdoor kitchen build may be more work than we originally thought."

Little by little we were able to break up the old concrete. We figured there was some settling going on underneath (giant crack was a dead giveaway), but we were shocked at the nearly 12" gap between the slab and the ground below.

And what was even more surprising, and frankly an all-out mystery, was the astounding number of tennis balls hiding below ground. We will never know where and when they came from, but the fact that one was actually molded into concrete makes us wonder if they've been there all along. We will never know, but our dog Uno will be forever grateful for the new toys we unearthed.

We soon realized that a jackhammer would also be required as we reached the thicker concrete of the steps.

Making the most of our "weekend warrior" rental of the skid steer, as soon as the old patio was gone, we quickly set out to mark the perimeter of the patio and began to dig the 6-10 inches required for the base materials that would go under the new pavers.

By the end of the first weekend we had certainly made a considerable dent but it was sadly only a drop in the bucket compared to the amount of work yet to be done.

As we sat back to admire the fruits of our labor we all agreed on one thing: While it's a TON bigger than what we previously had, it still wasn't big enough. We staked out the corner that would be the outdoor kitchen and realized that the remaining space would likely feel crowded once furnished with tables and chairs. So the next time we rented the skid steer (I believe we rented it 4 different weekends) we dug another 8 feet on the width of the patio.

The Not-So-Fun Underground Work

Since we decided that our DIY outdoor kitchen would be using electric, water (hot/cold/drain) and natural gas, there was a massive amount of work that would be required to run those lines from the house to their end destination. So we set out to dig the 18" trench in which they would be buried. Water and electric would come up at one end of the outdoor kitchen, and the gas would be coming up on the opposite side.

Since the outdoor kitchen would be sitting on a concrete pad (instead of pavers), we built a wood frame to pour that concrete into, which served as a guide on where to direct our trenches just right.

We also had to pour the concrete footers that the pavilion would later be built upon. Each of those 4 holes had to be dug 3 feet. That was a lot of work, even with the 2 man auger we rented.

Have I mentioned yet that there was an astounding amount of digging and preparation required before we could even think about laying down pavers? I think that may have been our biggest surprise in this project. We truly had no idea how much labor goes into things that are never even seen in the end. It definitely made us appreciate the quotes we received earlier on and helped us to understand why so much is charged for labor.

Once all the trenches were dug, the next step was to drill into the foundation of our house in order to run the water, electric and gas lines. 3 holes would need to be drilled. One for gas, one for the water drainage back to the house, and one for water and electric (in separate runs).

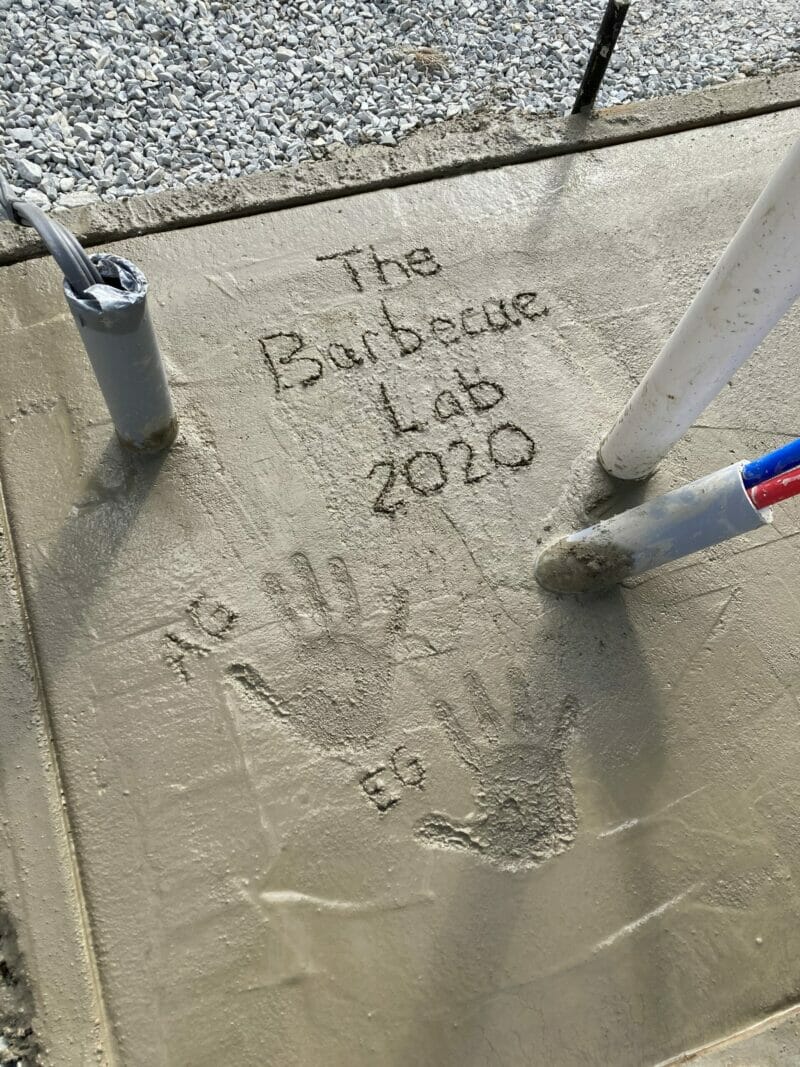

DIY Outdoor Kitchen concrete pad

Once all the underground work had been finished, the next step was to pour the concrete pad that the outdoor kitchen would rest on. The fresh concrete would need a few inches of paver base as a foundation. After tamping that down we secured the wood frame in place and then built up additional paver base all around it to prevent concrete leaking out from under the frame.

Building the Patio

Patio Paver Base

Before we could begin laying down pavers we had to give them a solid foundation to rest upon. We had seen for ourselves how much the ground had settled under the last patio, and we wanted to do whatever we could to prevent that from happening again.

After first laying down a layer of geotextile fabric, we had about 15 yards of paver base (called modified 53s in our area) delivered to our driveway which we then transferred to the backyard using the rented skid steer. We recruited a few friends to help us rake it all out and we used a rented power tamper to tamp it down every 2 inches.

This was the part of the process where setting the grade of the patio was critical.

Paver Sand

Once that was all set, we then had a load of paver sand delivered which we transferred by wheelbarrow to the back. The ultimate goal was to have a 1-inch layer of sand screeded smooth on which to lay pavers. And because it's hard to keep that much sand smooth and undisturbed while also laying pavers, this was an add-sand-and-screed-as-you-go kind of process.

Pavers

We created our own pattern using tumbled Belgian pavers in both 6x6 and 6x9 sizes, using 4 different shades: autumn, gray, sienna, and tan. Our goal was for it to appear random and we quickly discovered it took a lot of planning to achieve a random look without clumps of the same shade too close together.

We had 8 pallets of the different types of stones on the outskirts of the patio and labeled each pallet a letter A-H. Every row of pavers followed a different pattern using those letters. Someone was in charge of calling out the pattern for each row while we utilized other runners to deliver the correct stones to the brick layer.

Once again, this process took a lot longer than we anticipated. In order to do it right we had to take our time and not rush, and what we thought we could get finished in just a few days actually took a few weeks when all was said and done.

We might have ended up with some sore backs, carpel tunnel, tennis elbow, and a few smashed thumbs, but we got it done. And now every member of the family, as well as a few friends have invested interest in this outdoor space, and we can all share in those memories when we spend time out there together.

After laying the last brick there were still 2 important steps left before we could say the patio was officially finished. We had to sweep polymeric sand into all the cracks and crevices and spray it down to make that set. We also had to spray a sealer on the patio. Keeping the patio properly sealed is something that we'll have to repeat throughout the life of this patio.

Building the Pavilion

We considered saving the pavilion for later and forging ahead to the outdoor kitchen, but a friend of mine brought up a good point. It sure would be a shame to drop a piece of wood on a freshly installed stainless steel appliance, while building a pavilion over an already completed outdoor kitchen. That made sense to me as well as the idea that having a pavilion would provide shelter for us to work under if the weather was less than optimal.

We had prebuilt trusses delivered to our property that really helped the pavilion go up pretty quickly. I believe this build really only took us a few days to complete.

Now I'll be honest, I did pay someone to shingle the roof of the pavilion. We bought all the materials ourselves, but decided to hire help to install the shingles. Aside from hooking up the electric and gas, this was the only other service we hired out. Everything else we did ourselves.

Building the DIY Outdoor Kitchen

We broke ground in July and by the end of October we had finally reached the main event of the project: Framing up the outdoor kitchen.

We built the frame using 3-5/8" x 20 gauge and 1-5/8" x 20 gauge steel studs and track. We used aviation snips to cut them to the correct lengths and fastened them together with self-tapping screws and my impact driver.

For an added layer of precaution, we cut pieces of trex decking to place underneath the metal frame in order to prevent rusting from the steel studs sitting in standing water or snow throughout the winter.

Once we finally had the frame built and tested out the fit of all the fixtures, we then attached 1/2" cement board to the outside of the frame. We tried a piece of Durock, but were much happier with the cement board that we purchased from Foundation Building Materials.

We had to do a fair amount of trimming the cement board (using our circular saw with a cement saw blade) and the Durock brand we purchased from Menards just seemed to shred and fall apart when we had to cut it.

To attach the cement board to the steel studs we used cement screws.

We used a jig saw to create the cutouts for the vents and access doors.

Unfortunately we were ready to begin work on the stone veneer right when winter hit. Since it's recommended for concrete to cure at or above 50°F, we had to batten down the hatches with large tarps and put away our tools for a few months. At this point our 2 remaining tasks (veneer and concrete countertops) were both working with concrete.

Spring eventually came and we successfully talked ourselves into getting back out there to finish what we'd started.

We found putting up the veneer to be a frustrating process. It took us a while to figure out the best consistency for the concrete mixture. Not sure if it was a matter of mortar being too wet or too dry, or just the overall quality of the mortar we used, but about half of our first day's work ended up falling off when bumped them with the slightest pressure.

Eventually we found our groove, (or I should say Melissa did since she was the rock star doing this part of the job), and with a scratch coat and a wetter mix of mortar we got the rest of the veneer up. Melissa found the pointing tool and a small level to be major assets throughout this process in addition to the typical masonry hand tools.

Pouring Concrete Countertops

We used an inverse-pour method to build our concrete countertops. To make it sound a lot simpler than it actually was, it went a little like this:

1. Calculate how and where to segment countertop.

We had to figure out exactly where we needed to divide up the concrete countertops based on weight and counter-mounted appliance location. Since we weren't pouring in place, these would have to be picked up and moved to their final destination. The total weight of the whole countertop was 1,525 pounds, so we figured it would be best to break that up into more manageable pieces.

2. Build the forms.

Next we built a form out of melamine to the exact dimensions of one section of counter, but inverse. Top is bottom and left is right. This took some real brain power and double and triple checking measurements.

3. Seal seams with caulk.

Before we could do any pouring we had to seal all the inside seams with silicone caulk and clean, clean, clean the melamine. The concrete touching the melamine is the top of the counter so absolutely any blemishes would be visible in the finished product. We also sprayed the inside of the form with WD-40 to help the cured concrete release later on.

4. Mix and pour the concrete.

Now it was finally time to mix and pour the rapid-set concrete. Time was of the essence. Rapid set concrete does indeed set rapidly. We mixed in flow control to each bag in order to make the concrete easier to work with. (We highly recommend this addition). We also added a full bottle of concrete colorant with each batch to get the charcoal gray color we wanted. The eggbeater mixer attached to my drill made the task of mixing bags of concrete a lot easier.

5. Place the rebar.

Place fiberglass rebar throughout the form and gently pound the outside of the form with a mallet to release bubbles. (This step is absolutely critical. Don't ask me how I know.) Screed the surface smooth with a trowel.

6. Keep it damp.

Spray the surface with water every 10-15 minutes as it is curing.

7. Release it from the frame.

Supposedly the rapid-set would have been ready to release from the form in an hour, but we always saved that for the next day just to be on the safe side. Grab a few strong friends and very carefully tip the form over, releasing the finished concrete countertop smooth side up. Then carry it to it's final resting place in the outdoor kitchen.

8. Repeat.

Just repeat that whole process 7 more times. Easy peasy.

This was another fairly time-consuming part of the process that was also affected greatly by winter. We would have been ready to start pouring concrete countertops in December, but really had to wait until March due to the cold temperatures.

Because of the steps involved and the waiting periods that were required along the way, each piece of concrete countertop took 3 days to complete. We had the counter split into 8 sections and were only able to fit 2 forms on a single 4x8 sheet of melamine twice. So it took us several weeks to get all the pieces finished.

We included a 12 inch bar overhang on both sides of the U-shaped outdoor kitchen. In order to protect those sections of concrete from breaking under the weight of guests who might decide to lean on them, we got iron supports to install underneath each of those sections.

While the inverse pour did produce a nice smooth top, it still had a pretty matte finish. Using some advice from the concrete guru himself, Michael Builds (look him up on YouTube), we sanded through multiple diamond sanding discs with our polisher before finally sealing the tops.

The Finished Project

We broke ground on our DIY outdoor kitchen in July 2020. We placed the final stones of the outside facade at the beginning of June 2021. 11 months. ELEVEN MONTHS. 11/12 of a year.

Now to be honest, we weren't working on it all of the 11 months. There were at least 2-3 months during the winter that we weren't really able to make any forward progress due to the cold temperatures and we did truly enjoy the break and time to recover.

But now it is finally complete and we have had an amazing summer so far being able to enjoy the fruits of all our hard work.

So here it is: our DIY Outdoor Kitchen build.

Appliances, Drawers, and Doors

Pellet Grill

We selected the Memphis Pro to be our built-in pellet smoker/grill. We also selected the controller/drawer combo to go along with it. We are thrilled with our choice as it is easily the best pellet smoker that I’ve had the privilege to cook on.

Gas Grill

We selected the American Renaissance 36" gas grill to be our built-in gas grill. This dude is super heavy duty and has the ability to get rippin' hot for a really great sear. Use code: BBQLAB to receive a special gift with your order from RCS Gas Grills!

Pro Burner

We selected the American Renaissance pro burner to be our built-in side burner next to the gas grill. It is just so convenient to have a burner outside as we prepare the whole meal in addition to the main dish. And we especially love to pull out the center ring to use our round-bottomed wok. Use code: BBQLAB to receive a special gift with your order from RCS Gas Grills!

Griddle

We selected the LeGriddle 30" to be our built-in griddle. We use this griddle ALL THE TIME. It may very well be our most used appliance in the outdoor kitchen to be honest. Use code: BBQLAB to receive a special gift with your order from Le Griddle!

Kamado Grill

We built 2 spots for kamado grills into our DIY outdoor kitchen. Our plan is to keep an XL kamado on one side and a large size on the other side. Currently we have the new Vision Maxis on our XL side and our Solo Stove grill on the other side.

And while we're at it, we certainly have to mention the amazing kamado drawers for each spot. I love having these oversized stainless steel drawers to store bags of charcoal and oversized tools in.

Pizza Oven

We already had the Ooni Koda 16 pizza oven on hand, but we certainly made it a priority to leave plenty of space to house it in addition to pizza prep space. On the outside of the corner where the Ooni pizza oven sits, we've built a cabinet that stores the propane tank to fuel it.

Sink, Refrigerator and Ice Maker

The benefit of going DIY, is that it frees up extra money to splurge on some fun extras. We got the sink, ice maker, and refrigerator from RCS Gas Grills. These are likely corners we may have cut if we were paying for labor, but we're so glad that we didn't have to exclude them. Having these 3 features truly make it an outdoor kitchen rather than just a grilling space. Use code: BBQLAB to receive a special gift with your order from RCS Gas Grills!

Warming Drawer

Underneath our Memphis Pro we have installed a warming drawer from RCS Grills. This has been a perfect place to rest meat after it has come to temperature, as well as holding side dishes warm until meal time. Use code: BBQLAB to receive a special gift with your order from RCS Gas Grills!

Trash and Pellet Drawers

Probably my #1 favorite drawer we installed in the outdoor kitchen is the stainless steel trash drawer with the pellet drawer coming in at a close 2nd. The trash drawer is often one of the first things we point out when we're entertaining in the backyard. Use code: BBQLAB to receive a special gift with your order from RCS Gas Grills!

Storage Drawers

Because reviewing barbecue grills and gear is our job, we have big needs when it comes to storage space. And as you have probably noticed, we did not skimp when it came to drawers and storage cabinets. And believe it or not, we've got stuff in every single one of them.

The stainless steel double drawer and paper towel holder next to the triple drawer units are perfectly positioned under my prep zone to hold all the necessary tools and gadgets for that job.

We put a stack of accessory & tool drawers underneath our power burner to store all of our griddle tools, cooking utensils, temperature devices, Grill Grates, and cast iron pans.

Use code: BBQLAB to receive a special gift with your order from RCS Gas Grills!

How Much Money Did DIY Save Us?

Quoted Including Labor | DIY Cost | |

|---|---|---|

Demo & removal of old patio | $1,900 | $800 |

Paver Patio | $24,665 | $7,900 |

Pavilion | $10,000 | $2,700 |

Outdoor Kitchen (minus fixtures & appliances) | $25,000 - $60,000 | $2,287 |

Total Cost | $61,565-$96,565 | $13,687 |

We would like to give a heartfelt thanks to RCS Grills, Memphis Wood Fire Grills, Vision Grills, and Ooni Pizza Ovens for their partnerships that made so much of this project possible.

We would also like to thank our family and friends who gave of their time and energy to help us tackle this crazy project. You have all earned your own seat and free meal out back any time.

Whether you do the labor yourself, or pay someone else to do all the heavy lifting, having your own outdoor kitchen is an amazing thing.

Summer evenings spent outside cooking in our very own outdoor kitchen and gathering with family and friends are my favorite.

Update: A Year+ Later

We've been using our DIY modern outdoor kitchen for over a year now. Some might be wondering how it's holding up? Do we have any regrets? Wish-we-would-have's?

Bigger WAS Better... for us.

We are SO glad that we made that call on that first weekend to go bigger for the patio. I don't know that everybody would have necessarily needed that extra outdoor space, but we certainly use every square inch of it running this website and YouTube channel.

Filming for "The Best Pellet Grill Under $599 took up a lot of space on our patio.

Our XL patio was a great place to film the "Best XL Kamado" video.

Critter Control

We did continue to use the outdoor kitchen (in a more limited capacity) through the winter but there were certain parts of it that went unused for a couple of months in the super cold and snow filled months. I should say, "unused... by us." As it turns out, there were several parts of the outdoor kitchen that seemed to be used quite regularly by some very tiny and unwanted guests.

Some of the drawers that we installed were fully enclosed, while others were not. When the cold weather broke and we resumed full use of the outdoor kitchen it became very obvious which drawers were which, and some meticulous deep cleaning became top priority.

If we had it to do over again, we would have probably attempted to install cabinet doors and drawers that were fully enclosed more than not. In addition to keeping the unwanted critters out, those drawers do a much better job of keeping the contents dust free.

Now that we know what we know, we'll take some additional steps as we "winterize" the outdoor kitchen next fall.

Our Sometimes Fragile Facade

We shared up above that applying the stone veneer to the outside of the kitchen was a frustrating process. It has mostly stayed up and behaved as expected. However, there have been a few bad apples that don't seem to want to stay in place. Generally they've been the little pieces that we've cut to fit in small spaces.

We knew when we opted for maximum storage space in our own outdoor kitchen that it would complicate the outer facade and that was the case for sure. We just deal with it and keep a tube of construction adhesive handy.

If we had to do it again we might have used wire lath between the concrete board and the scratch coat, but that would have still been a challenge in those small spaces between the doors and drawers.

In the end, I think that ultimately, a few fallen facade pieces are just the price we pay for the sheer volume of storage options we put in our outdoor kitchen plan. Like I said... construction adhesive is our friend now.

There's no better place to gather with a few friends and family.

We have entertained countless groups of people in this outdoor space since finishing it over a year ago.

Whether it's a Friday night pizza party around the Alfa 4 Pizze pizza oven, or celebrating 50 years of marriage with family, this space is for being together.

And that right there makes it all worth the work we put into this outdoor kitchen project.

Paul Osiecki

December 26, 2021 9:30 pmDavid – you are teaching me a lot, since I am in the process of building my outdoor kitchen. Do you have any videos on installing the electric and gas into your kitchen? I have a backsplash where I want to put my outlets plus light switches. Not sure how to do this. Also, the veneer is something I have no experience with. Do you have videos on installing this or recommend other videos? Thanks so much! PLEASE keep up the videos, you do a great job.

Thanks,

Paul

David Gafford

December 29, 2021 2:46 pmHi Paul, We do have some videos coming up that will cover veneer, running electric and gas underground and a bunch of other things from the build. Keep an eye on the website and YouTube channel for those coming soon.

Chere’ Sterk

February 6, 2022 8:31 pmWow I really appreciate all the break down of costs and labor. What a lot of work! We really want to do something like this. After reading this we will really have to dive into the facts of everything involved. The finished product is unbelievable. Absolutely gorgeous and could be in any magazine featuring outdoor kitchens and entertainment spaces. Truly changed your entire yard probably are the envy of every neighbor! But if they want what you have then they can go through the pain and process and have this as a show peace in there yard haha! Next time I see a outdoor kitchen I’ll say to myself…wow that was a lot of time work money and it’s a masterpiece!